Powder Compaction Solutions

Industrial Solutions

Powder Compaction Solutions

Powder compaction is the process of compressing metal powder in a die by applying high pressures. This compression molding technique typically involves using a press to condense the powder into complex shapes from powder compounds like metallic, composite and ceramic to create functional and structurally sound metal parts.

Gasbarre Products, Inc. is a leader in manufacturing of mechanical powder compacting and sizing presses.

Gasbarre’s products and services include amongst others:

- Start-to-finish Equipment

- Development and Manufacturing Projects

- Design & Maintenance of Presses

- Spare Parts & Tooling

- Machine Upgrades

The Gasbarre Family:

- Simac Ltd.

- PTX-Pentronix

Steve Urbanczyk

Ask me for more information.

+49 (0) 2244 918 130

SIMAC Series V Monostatic Press – Automatic Pressing

When it has to be efficient, it has to be Gasbarre!

Gasbarre’s state of the art isostatic press, featuring a fully automatic ‘lights out’ cycle to mass produce rods, tubes, and balls.

Key Features:

- Fast Cycle Rate: 48 Second Cycle

Almost 2x faster than previous models - Dry Bag CIP Design

Simplifies the cycle and allows for clean changeover. - Versatile Tool Envelop

Allows for fill diameter up to 50mm and length up to 500mm. - Electronic Powder Weighing System

Accurate to 0.01g. - Intuitive HMI

Creates an easy platform for new part development and quick changeover.

Maintenance alerts, alarms and production tracking/tracing

Whether for laboratory or production, Gasbarre’s SIMAC product line fits your needs by offering uniquely configures presses to produce uniform density components. The dry bag design simplifies powder filling, compaction, and ejection and is more efficient allowing for quick changeover of application tools.

SIMAC presses include a tool mounting system that allows for a wide range of parts to be produced in the same machine. Dual inner bag configuration allows simple tool changeover.

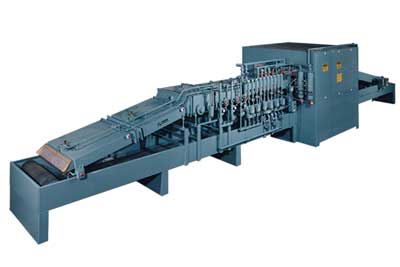

Presses

A full range of powder compaction and sizing solutions for a full range of applications. Gasbarre has decades of press building experience, offering standard and custom equipment solutions. Auxiliary equipment and worldwide support mean that Gasbarre will be with you throughout the life of your press.

Isostatic Presses

From the world leader in dry bag cold isostatic press technology. Available in single or multi-cavity.

Mechanical Presses

Press capacities range from 5 tons to 800 tons. Designed for simple-to-complex multiple level components.

Hydraulic Presses

Manufactured in capacities from 15 – 1,200 tons for single-level or multi-level parts.

Electric Presses

Leading edge electric press technology from the world leader in powder compaction presses.

You are looking for Molding Bags and Sealing Membranes for your presses. Then we are the right partner for you. You can find more information here.

Thermal Processing Systems – Industrial Furnaces

About

Gasbarre

Gasbarre, headquartered in DuBois, PA, was founded in 1973 to design, manufacture, and service a complete line of powder compaction and sizing presses for the powder metallurgy industry. Since that time, Gasbarre has earned a worldwide reputation as a full service supplier to the powder metallurgy, particulate materials and thermal processing industries.

With over 200 employees in seven locations, Gasbarre stands alone in the ability to offer equipment and services for all applications related to powder compaction and thermal processing. Today, with 20% of Gasbarre products being exported, there are thousands of Gasbarre presses, furnaces and other equipment in operation all around the globe.

Gasbarre Products, Inc.

DuBois, PA | USA

Established in 1973

ISO 9001 CERTIFIED

ISO 17025 CERTIFIED

JVS Sales & Technical Consultants GmbH

We are here for your ideas.

Deep Drawing

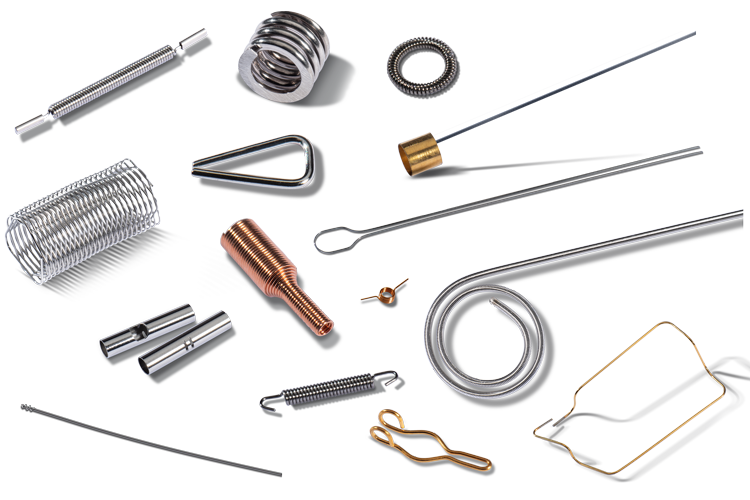

Micro Springs & Wire Forms

Metal Cutting

Machining

Ultrasonic Machining

Powder Compaction

Thermal Processing

Surface Coatings

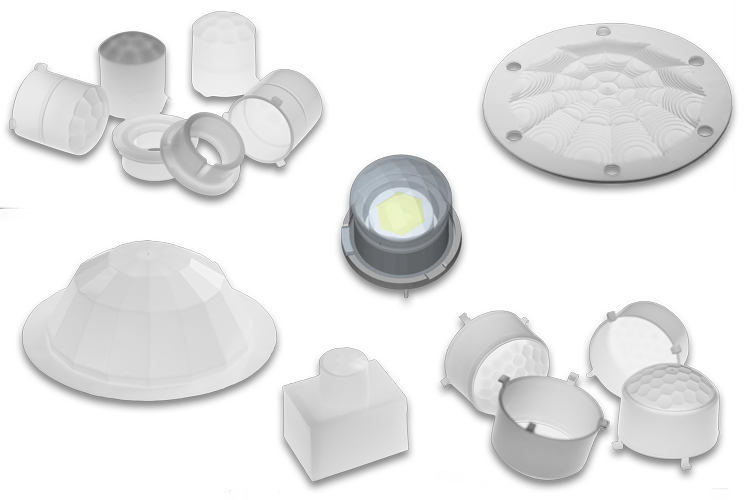

PIR Lens Solutions