Precision Micro Springs

& Wire Forms

Small parts. Big solutions.

Precision Micro Springs & Wire Forms

Motion Dynamics Corporation manufactures custom micro springs, medical coils and wire components that solve our customers’ problems in the shortest possible time, no matter how complex or seemingly impossible. We are also experts in laser welding and guidewires and specialize in the design, production and assembly of high quality wire components for medical device applications.

Specialties include capabilities with fine and ultra-fine wire diameters as well as unique alloy types and shapes. We only produce custom components therefore we do not stock any product. Motion Dynamics manufactures to the highest standards, from quick prototypes to large quantity production, for the medical, electronics, aerospace and military industry or any market needing the perfect custom wire component. ISO certified and ITAR registered.

Ask us for more information.

+49 (0) 2244 918 130

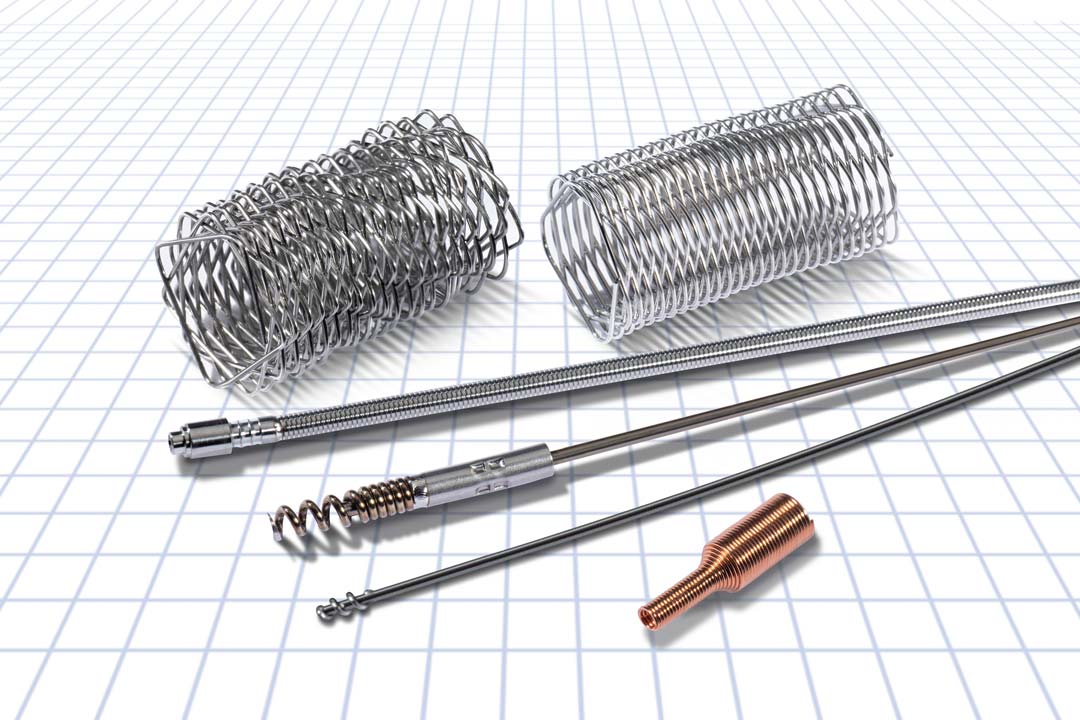

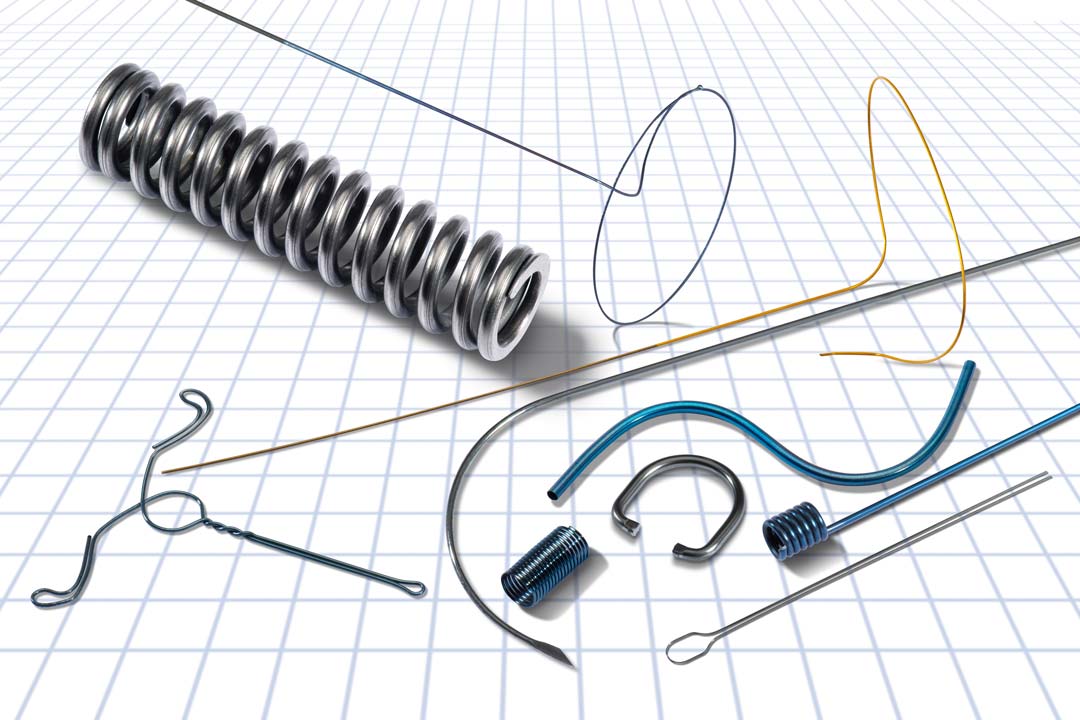

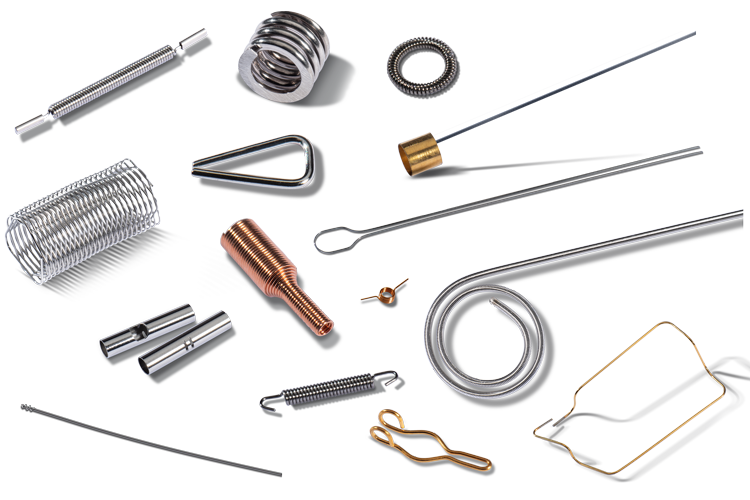

Micro Wire Components

We craft some of the smallest wire components in the world – including Micro Springs, Medical Coils and Guidewires – working with any cold formable material in sizes down to 0.0005″. The design of wire components in this scale can be very difficult and different than conventional sizes, which is why much of our technology is proprietary and developed by the Motion Dynamics team who specializes in this micro capability. Some of the types of Micro Springs we manufacture include:

- Compression Springs

- Torsion Springs

- Extension Springs

- Wire Forms

- Garter Springs

Micro Springs

Manufacturing Micro Springs is one of our specialties. We often assist our customers in developing their micro spring designs, however, ultimately we build products to their drawings and specifications. We operate under a comprehensive quality program (ISO Certified) and support our processes with solid documentation, traceability and service. With every shipment you get the following documentation (unless specified differently):

Final Inspection Report – includes critical dimensional data

Material Certification – Motion Dynamics’ certification of material size and tolerance, chemical properties and tensile strength.

Nitinol Components

Nitinol is the common name used for the shape memory alloy Nickel Titanium (NiTi) and is derived from its place of discovery (Nickel Titanium Naval Ordnance Laboratory). It is uniquely different then typical wire alloys used for cold forming or coiling wire components. A reversible, solid phase transformation (known as martensitic transformation) is the force behind shape memory alloys. The material forms a crystal structure, which is capable of undergoing a change from one form of crystal structure to another. Temperature change typically initiates this transformation in the following way:

- Above the transformation temperature – Nitinol is super-elastic, able to withstand deformation when a load is applied and return to its original shape when the load is removed.

- Below the transformation temperature – Nitinol displays the shaped memory effect: when deformed, it will remain in that shape until heated above its transformation temperature, at which time it returns to its original shape.

Nitinol is typically composed of approximately 50 to 55.6% nickel by weight with the balance being titanium. Making small changes in the composition can change the transition temperature of the alloy significantly. These unique properties make Nitinol suitable for many different types of applications, particularly in medical devices.

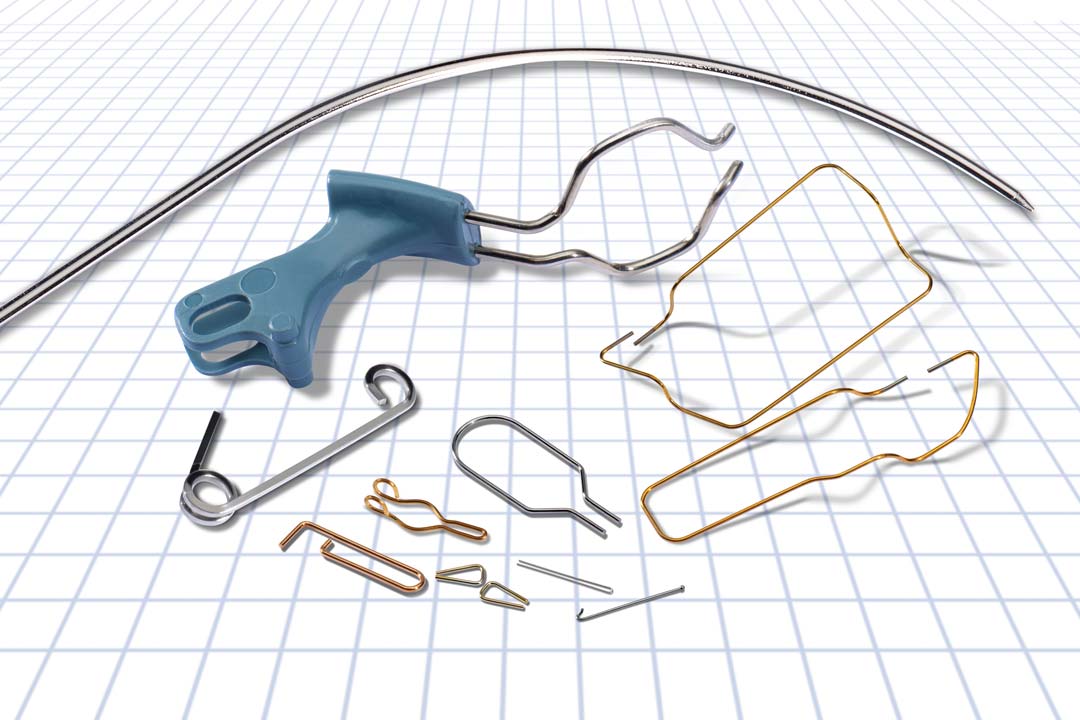

Wire Froms

A wire form is a general term used for almost any shape of wire component other than the conventional compression, torsion or extension springs. These forms are designed for custom applications and typically perform some spring function. Motion Dynamics Corporation has designed and built custom machinery dedicated to manufacturing tight tolerance, high precision wire forms at a fast and efficient rate. From the simplest to the most complex geometries, we have the equipment to provide you with either a prototype or millions of pieces, and the expert team to assist you with…

- Wire forms from any alloy including Nitinol

- Wire forms from any shaped material

- Straightening and cutting wires to any length

- Wire sizes from 0.001″ to 0.070″ depending on shape and material type

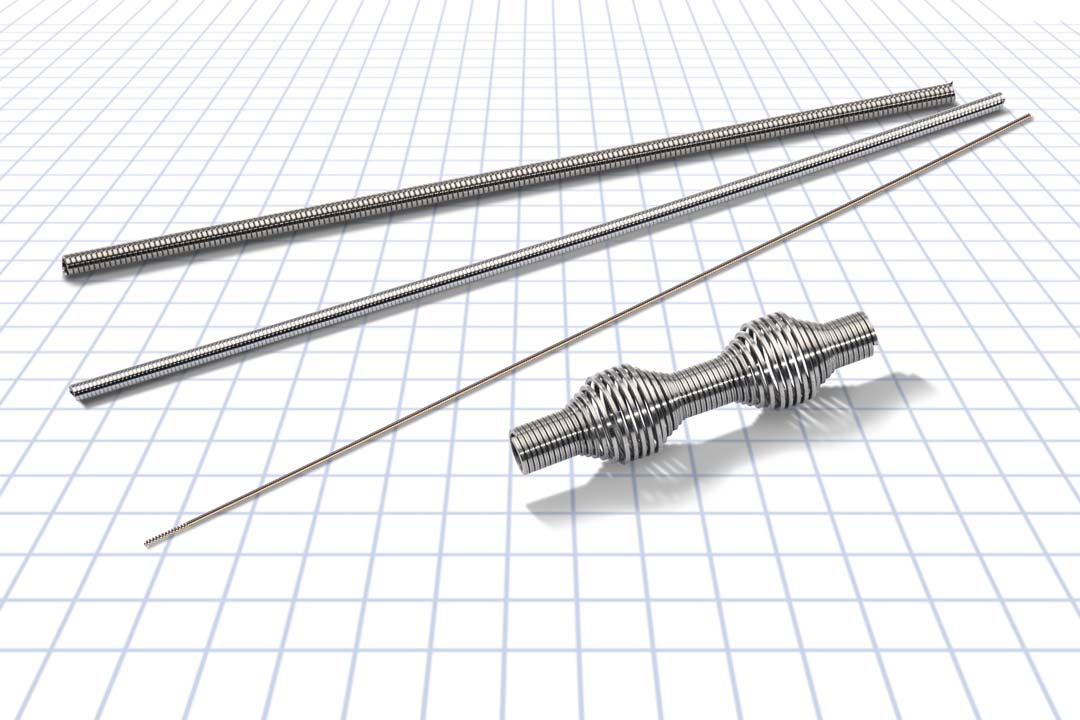

Windings

Wire windings are wire components manufactured by winding the wire around a mandrel or arbor to produce the final product. This process offers some advantages over deflection coiling by driving the wire into tooling that deflects the wire into the desired coil diameters. Winding can provide tighter OD/ID tolerances while deflection coiling offers greater variation in design. Types of windings we provide include:

- Closed

- NiTi Coils

- Ends Ground & Not Ground

About

Motion Dynamics Corporation

Our 73,000 sq. ft. custom-designed headquarter is located in Fruitport, Michigan. Built in 2015, our facility houses state-of-the-art CNC coilers, winders and formers custom built to satisfy our customers’ requests; as well as an on-site gym, collaborative areas, and modern work spaces.

Our culture is as unique as the solutions we provide and our highly-skilled and experienced team possesses an unwavering desire to push the boundaries of what can be done.

Motion Dynamics Corporation

Fruitport, MI | USA

Established in 1992

ISO 9001 and ISO 13485 Certified

RoHS2 (2011 Directive/65/EU) Compliant

REACH Compliant

DFARS Compliant

NNSA Compliant

JVS Sales & Technical Consultants GmbH

We are here for your ideas.

Deep Drawing

Micro Springs & Wire Forms

Metal Cutting

Machining

Ultrasonic Machining

Powder Compaction

Thermal Processing

Surface Coatings

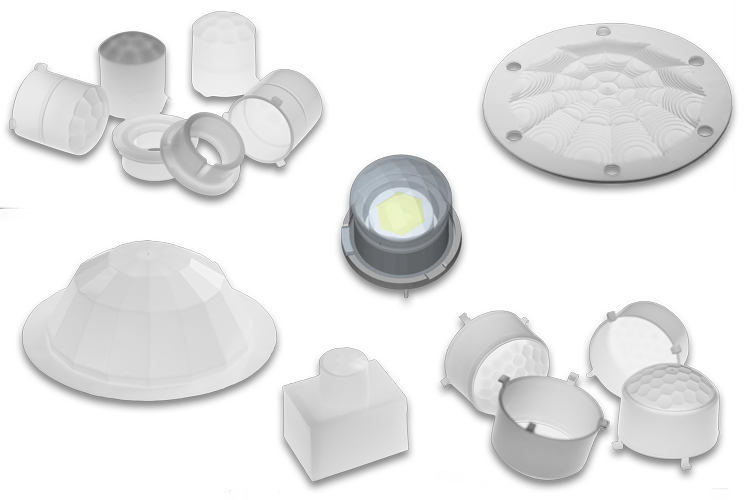

PIR Lens Solutions