Customised Components & Assemblies

Technical Solutions

Customized Components & Assemblies

Our machine shop is equipped with sophisticated production machineries such as, CNC turning centers, Multispindle Automats, Vertical machining Centers, & More than 25 Swiss Sliding Head Automats & various Special purpose machines, Broaching machines, leak testers, ultrasonic cleaning and leak detectors, to name a few. We strive for continuous improvement in our operational areas by incorporating technological advancement throughout the organization.

-

CNC Turning

-

CNC Drilling

-

CNC Milling

-

Centerless Grinding

-

Roll Threading

-

Internal Threading

-

Broaching

-

Vibro Finishing

-

Embossing

Stainless Steel Cable Ties

Stainless Steel Roller Ball Lock Cable Ties.

- Self Locking mechanism for fast and easy installation

- Rounded edges and Smooth Surfaces for safe handling

- Flame Retardant, Non-Toxic and Halogen Free

- Fully enclosed head does not allow dirt to interfere with locking mechanism

- Ideal for applications where Corrosion,

- Vibration, Radiation and Temperature extremes are concerned

- Cable Tie Lock Mechanism Ball made of SS316 ensuring perfect lock in harsh corrosive conditions

Technical information:

-

Cable Ties are available in Metallic (Stainless Steel 316/304)

-

Operating Temperature Range –

-40°C to 300°C for Uncoated Ties

-60°C to 160°C for Coated Ties - Surface Finish – Metallic for uncoating and Pure Polyester / Epoxy blend for Coating

- Flammability Rating – Fireproof , Halogen Free and UV resistant.

- Type Tested for Fire Rating & short Circuit Testing

Die Cast Aluminium Enclosures

Aluminum Enclosure Specification:

- Material : EN AC-AlSi12 9(Fe) as per DIN EN 1706

- Gasket : Silicon, Neoprene, EMC/RFI Shielded

- Lid Screw : Stainless Steel 1.4301 ( A2), Captive M4/M6

- Operating Temperature Range : -60°C to 150°C

- Ingress Protection : IP 66 & IP68 for Standard Enclosures & IP69K (Under Approval) As per IS/EN 60529-2001.

- Standard Colour : RAL 7001,7032 & RAL 9005 and many more available on request

- Impact Resistance :

1. Empty Enclosures: IK09 (10J) as per EN 60079-2007

2. Fully Assembled Enclosures: IK-08 (7J) with IP-68 Certifications. - External Earthing : Stainless Steel external Stud.

- Corrosion Resistance: >1000 Hrs as per ASTM B-117

Customization:

- Any Colour Powder Coating

- Drilling Holes

- Tapping for Threaded Holes

- Any Shape Cutout Machine

- Engraving

- Printing

- Clinch Stud Fixing

- Asssembly

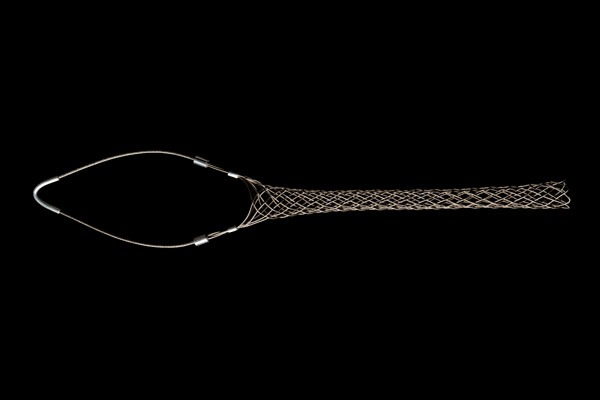

Cable grips / Cable Socks / Cable Stockings / Wire Mesh Grips

Cable grips, also known as cable socks, wire mesh grips or cable stockings, are flexible devices typically made from woven steel wires or synthetic materials. Their primary function is to provide strain relief, pulling, support, and protection to cables and wires. These grips are designed to secure cables firmly in place while allowing for movement and flexibility, thereby preventing damage from bending, torsion, or vibration.

- Pulling Grips

- Heavy Duty Grips

- Support Grips

About

TF4 Global

TF4Global is a leading “Make in India” company that specializes in manufacturing and supplying of high-quality metal engineering components and assemblies and cable accessories products including Stainless Steel Cable Ties and Die Cast Aluminum Enclosures to Global Original Equipment Manufacturers (OEMS).

TF4 Global

Golani Naka | India

Established in 2021

ISO 9001

ISO 14001

ISO 45001

JVS Sales & Technical Consultants GmbH

We are here for your ideas.

Deep Drawing

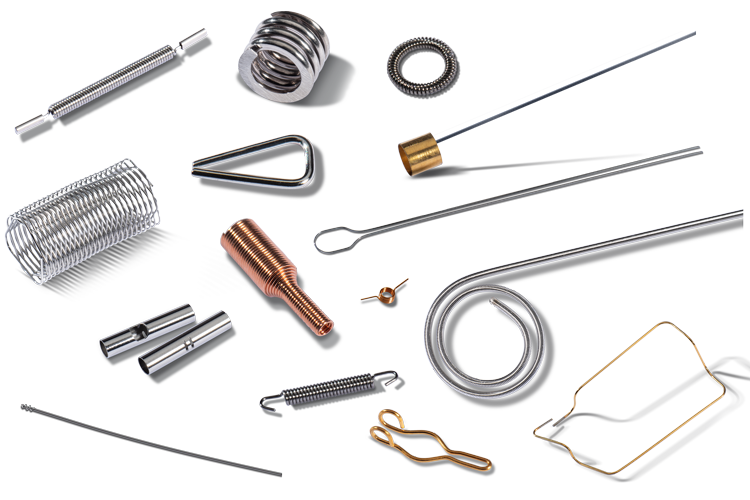

Micro Springs & Wire Forms

Metal Cutting

Machining

Ultrasonic Machining

Powder Compaction

Thermal Processing

Surface Coatings

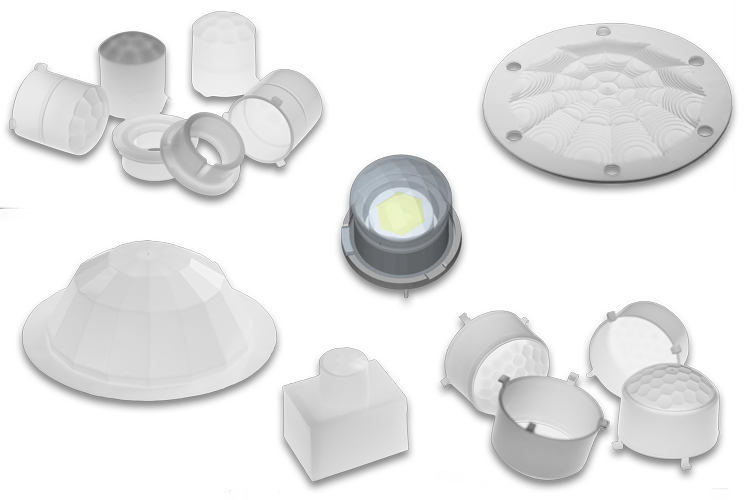

PIR Lens Solutions